FibreCoat GmbH, based in Aachen, Germany, has unveiled a groundbreaking fiber‑reinforced composite reportedly capable of drastically reducing radar cross-section (RCS), making platforms far harder to detect. This innovation marks a strategic evolution in passive stealth materials, shifting from reflection-based coatings to materials that actively absorb radar energy.

Strategic context: why passive stealth matters now?

Modern armed forces face increasingly capable detection systems: advanced radar, airborne surveillance, persistent ISR platforms. As a result, investments in passive stealth, reducing signature without the cost, weight, or power consumption of active measures, are surging. Materials that absorb radar rather than reflect it offer a discreet layer of protection for future platforms.

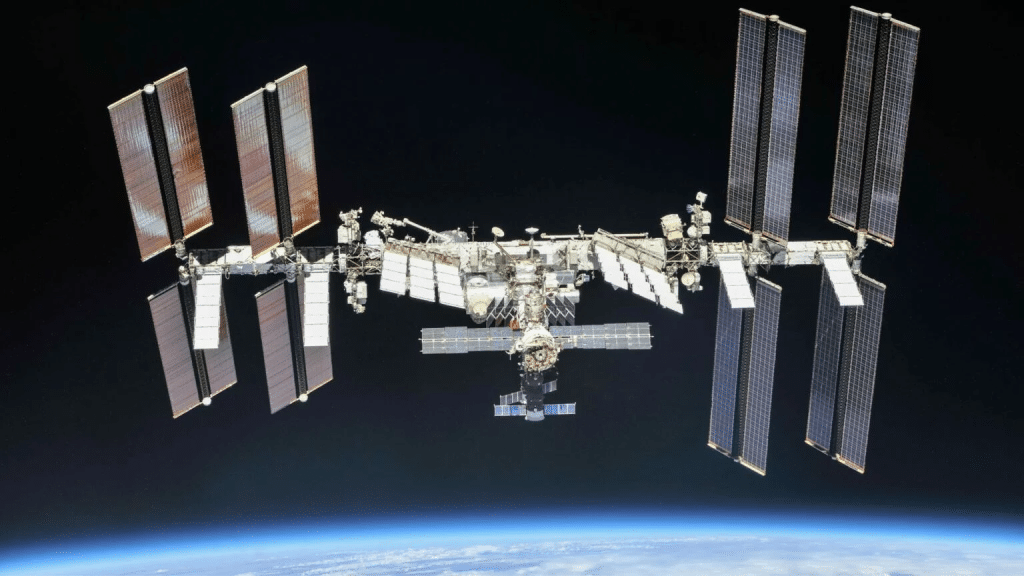

For Europe, with its emphasis on strategic autonomy and dual-use innovation, homegrown deep tech firms like FibreCoat become pivotal. Their composite aligns with continental needs: lightweight, modular, cost-efficient stealth solutions for both defense and space.

FibreCoat’s position in the value chain

Founded in 2020 and spun out from RWTH Aachen, FibreCoat has raised nearly €20M in Series B funding to scale its coated-fiber technology. Investors include NewSpace Capital, Goose Capital, and Nova Saint‑Gobain.

The company’s patented bi-component multi-filament yarns combine basalt or glass cores with aluminum coatings (Alucoat), carbon nanotubes, PMMA and other conductive fillers to deliver EMI shielding, thermal resistance and structural strength in a lightweight package.

FibreCoat thus sits at the intersection of materials innovation, European deep tech entrepreneurship, and defense‑dual‑use strategy.

Innovation beyond traditional stealth coatings

Unlike conventional radar absorbent paints or tile‑based RAM coatings, FibreCoat’s composite achieves up to –40 dB reflection loss, meaning ≈99.99% of radar waves are absorbed. This performance is maintained across curved surfaces and wide incidence angles (≥ 60° TE mode, ≥ 45° TM mode), a major design advantage.

The composite’s thickness ranges from 0.5 mm to 6 mm, ultra-thin compared to legacy methods, has the potential for integration on UAVs, land vehicles or structural panels, pending successful field validation.

In the words of CEO Dr. Robert Brüll: “We’re moving stealth technology beyond the limits imposed by needing to reflect, rather than absorb radar waves. Absorption opens up a range of new possibilities… giving designers more freedom.”

Operational implications for NATO and European defense

For platforms such as MALE UAVs, loitering drones, light armored vehicles and even naval auxiliaries, passive stealth coatings can drastically reduce RCS without major redesigns. FibreCoat’s modular composite allows retrofit and new-build integration, enabling future conflict architectures with stealth built-in, not appended.

Its dual-use profile, suitable for both defense and space applications, supports European goals of technology sovereignty.

Challenges & next steps

So far the material is at proof-of-concept stage, with field testing expected soon. Supply chain resilience, validation in operational radiation environments, standard compliance, and cost-effective scaling will be key hurdles.

Yet with nearly €20M funding, European R&D roots, and growing partnerships, FibreCoat is well-positioned to meet rising demand. The company aims to become a leader in high-performance stealth materials globally.

FibreCoat’s stealth composite represents a strategic breakthrough, ushering in a new paradigm where radar absorption, not reflection, is central to passive survivability. Its light weight, broadband absorption, modular application and European roots position it as a rising key player in the evolving defense materials landscape. As testing progresses, its impact could ripple through drone, naval and armored vehicle design philosophies, shaping the future of stealth technology.